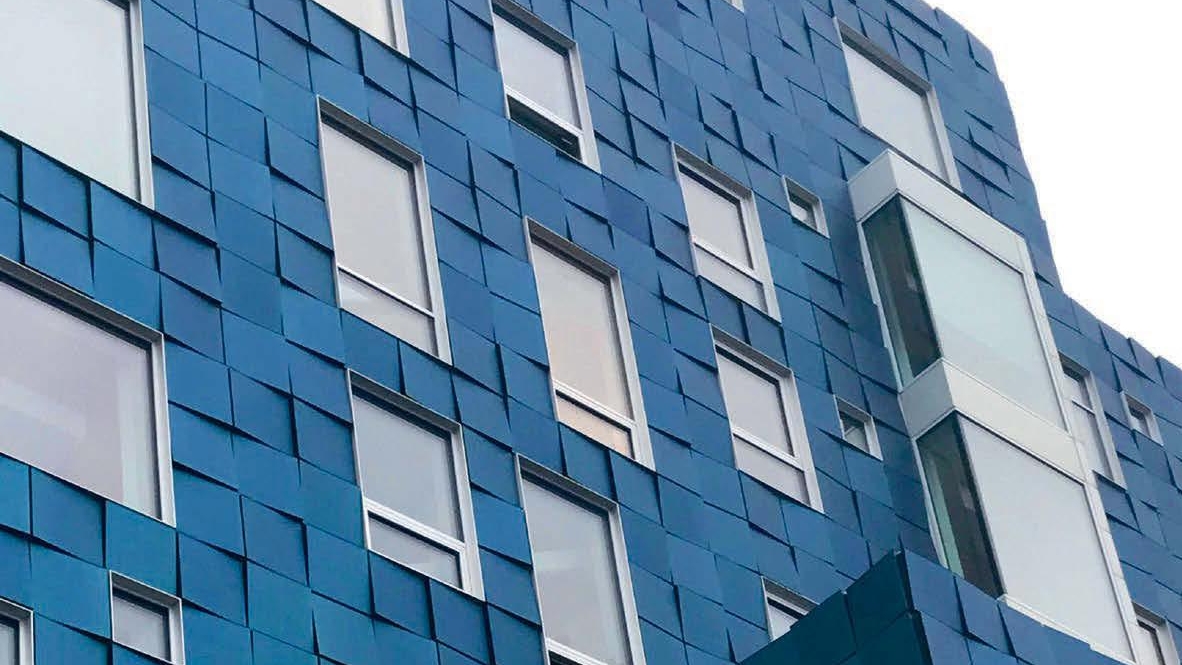

The Copenhagen International School Building in Denmark – successful use of BIPV. Image © Dr Rebecca Jing Yang

Microsoft co-founder Bill Gates recently mentioned on LinkedIn that the world will effectively be building another New York city every month for the next 40 years. Construction on such a huge scale raises concerns about carbon emissions in building development and operation, and Gates thinks that reducing the embodied energy in building materials and energy use in operation would be two ways that the sector could take action.

Among all the options he proposes incorporating solar panels into the building envelope is one of the most promising. Such building-integrated photovoltaics (BIPV) can be used to replace conventional materials in, for instance, the roof, skylights and facades. Unlike other distributed renewable technologies, the PV modules become construction elements while also providing building protection, aesthetic value, thermal comfort and electricity.

According to a Swiss study, BIPV can reduce the life-cycle greenhouse gas emissions of a building by between seven and nine per cent, and the total environmental impacts by nine to ten per cent. The latest costings from Danish BIPV company Ennogie estimate USS$135/m2 with a typical roof-integrated thin-film BIPV system, which converts 12 per cent of solar energy received into electricity; while Chinese BIPV company Helios estimates around US$115/m2 with a roof-integrated silicon PV system of 18 per cent efficiency. As well as being economically feasible, the systems are easily installed by a specialist.

From an aesthetic perspective, colourful PV panels can also be suitable for a range of building designs as well as satisfying most of the building markets needs. Costs will soon be cheaper still because global PV firms such as Sunman and Hanergy have invested significant resources in BIPV. Many BIPV projects have been developed on residential, commercial, industrial, educational and historic buildings, especially in Europe, and the report BIPV Technologies and Markets: 2015-2022 forecasts that the technology will represent 13 per cent of the PV market in two years' time.

"From an aesthetic perspective, colourful PV panels can also be suitable for a range of building designs"

In some countries, though, uptake is relatively slow in comparison to rooftop PV; for example, less than 1MW of BIPV was installed in Australia in 2016, which is significantly less than the roof-mounted capacity in the country, which totals 780MW.

Furthermore, as a product that affects the work of all professionals from design to construction and operation stages, BIPV use is regulated by building and construction standards; however, awareness of BIPV products and standards is limited because of information gaps in and between the PV and building sectors.

In 2019, my research team interviewed 102 stakeholders in the Australian building and PV sectors, and in September the findings were published in the report Cost reduction and deployment of prefabricated building-integrated photovoltaics, commissioned by the RICS Research Trust. The main aim of the study was to explore building professionals current concerns about using BIPV products, and BIPV manufacturers' major marketing hurdles. The key concerns we found relate to the accessibility of product information, compliance with building codes, and economic value. We also compared 27 popular PV design software products and apps: none had been developed specifically for BIPV, and none can address these concerns easily.

Building owners and surveyors need to understand the value and quality of BIPV products at the concept design stage, well before detailed design, because the technology requires substantially more capital investment than rooftop PV and the initial building design can affect cost and energy generation significantly. Detailed designs do not allow the major changes necessary to incorporate BIPV and the report proposes to treat it as a prefabricated active solar building element, with a comprehensive design stage so insights from PV and building consultants can inform product manufacture.

Since most BIPV products are pieces of prefabricated facade with PV inside them manufactured in Europe and China, quality assurance becomes a hurdle when selling them on a new market.

The flammable cladding issue has also drawn a lot of attention in Australia, and remains a concern for such products. Beyond this, a BIPV product needs to be certified by national accreditation bodies from both building and electrical sides, and its long-term performance must be monitored and validated.

Our research team is therefore applying blockchain technology to check and monitor quality in prefabrication and installation, and developing a database of BIPV products and standards to inform global manufacturers on relevant regulations in Australia. BIPV products usually conform to the International Electrotechnical Commission and ISO standards; however, the lack of specific BIPV standards in most countries makes dealing with local building codes a complicated task. BIPV differs from other cladding materials, especially in terms of wiring, and the detailed requirements for installing it are beyond the expertise of PV specialists.

The International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS) Task 15 includes more than 60 academic and industry experts from 17 countries, and is endeavouring to accelerate the BIPV market. Several reports are available from phase 1 of this task. Phase 2 began in January, will run for the next four years and aims to understand the technical innovation process, learn from current installations, develop industry guidelines, digitise project modelling and assessment, and research product characterisation methods.

BIPV will not totally replace roof-mounted PV, but targets a separate market segment with its unique benefits. Collaborations between all BIPV stakeholders. across the PV, energy, building and regulatory sectors will enhance product and standards awareness and help develop cost-effective approaches. IEA PVPS Task 15 and my team both welcome all collaboration to enable wider uptake.

Dr Rebecca Jing Yang is a senior lecturer and director of the Solar Energy Application Laboratory at the School of Property Construction and Project Management RMIT University Melbourne Australia rebecca.yang@rmit.edu.au

Related competencies include: Sustainability

BUILT ENVIRONMENT JOURNAL

Neil Hope-Collins 16 April 2024

PROPERTY JOURNAL

Zhana Lennox MRICS 12 April 2024

BUILT ENVIRONMENT JOURNAL

David Browne 09 April 2024