White Collar Factory, a 17-storey new-build office in Old Street, London. The construction team achieved an Outstanding BREEAM rating and 50% of the cement was replaced with ground granulated blast-furnace slag (GGBS) to reduce the carbon content ©Timothy Soar

Concrete, and the cement used to make it, are essential materials for our national economy and our way of life. New homes, schools, hospitals, workplaces, roads and railways, as well as the infrastructure that provides us with clean water, sanitation and energy all require these materials.

Concrete manufacturing takes place across the length and breadth of Britain. As an inherently local material with a short supply chain, the average ready-mix concrete delivery is around 12km. More than 95% of UK concrete is produced in the UK supporting local jobs and the economy.

Lying at the heart of the construction supply chain, the concrete and cement sector is a key part of a combined mineral products industry, which contributes around £16bn to the UK economy and employs 81,000 people, while supporting a further 3.5m jobs.

Despite this, the UK concrete industry is under no illusion about the need to decarbonise. Mineral products such as cement and concrete are extracted and produced in large quantities, and there is a corresponding impact on the environment – not least through the generation of carbon dioxide.

The main carbon emissions associated with concrete derive from the production of clinker, the principal ingredient in cement. These arise from the combustion of fuels in the kiln and as a natural by-product of the chemical reaction that makes cement.

Against the backdrop of a climate emergency and the UK's binding net-zero targets, there are currently a lot of misperceptions being created around the perceived problems with cement and concrete.

Indeed, some people argue that concrete should be replaced with alternative materials such as timber. They often argue for this without properly understanding the steps the UK concrete and cement industry has been taking and continues to take to cut carbon. Furthermore, an uninformed comparison of building materials often omits the way concrete can be specified to provide energy-efficient, low-carbon, safe and resilient buildings.

For example, the idea that timber products from commercial forests is sustainable is a concept increasingly subject to challenge. Of course, there is room for all products, but I believe we need a far more informed and intelligent conversation about the materials we use across the built environment so that designers and policymakers make the right choices when it comes to reducing carbon emissions. The stakes for humanity are now very high so separating the facts from fiction and helping to make the right choices are therefore important.

Roadmap to net zero

The UK concrete and cement industry has taken early action to reduce carbon emissions. Because it has already invested in switching from traditional fossil fuels to waste and waste-derived biomass, changes in product formulation, and energy efficiency including plant rationalisation, the industry's carbon dioxide emissions are 53% lower than in 1990. This has helped the sector to decarbonise faster than the UK economy.

Building on this decarbonisation, the industry is committed to reducing emissions from the built environment and supporting the government's net-zero target. Critically, it also plans to do this without offsetting emissions or offshoring production facilities.

The UK Concrete and Cement Industry Roadmap to Beyond Net Zero sets out an ambitious and robust plan to take the industry beyond net zero to become net negative. Industry experts carried out a detailed analysis to inform the creation of the scientific model upon which the roadmap is founded.

The roadmap identifies seven carbon dioxide-reduction technology levers that will reduce carbon emissions and in addition it defines the policies and collaboration that are required to support them.

- decarbonised electricity

- decarbonised transport

- low-carbon cement and concrete

- fuel switching

- carbon capture, use and storage (CCUS).

- carbonisation

- thermal mass.

A net carbon-negative industry can be achieved by 2050 thanks to the natural, in-use properties of concrete. These include its ability to absorb carbon dioxide during its long lifetime – carbonation – and the benefit of using the thermal properties of concrete – thermal mass – in buildings and structures to reduce operational emissions.

For the concrete and cement industry to get to net zero and beyond that, to become net negative, significant technological, structural and behavioural changes are required by our industry, clients, and specifiers of construction materials across buildings and infrastructure – as well as investment and buy-in from government.

The roadmap shows that the UK concrete and cement industry can be part of creating a net-zero economy that can help support jobs in the UK and tackle climate change. With a credible roadmap in place, wider society will benefit from net-zero concrete as well as the material's fire protection, resilience and durability.

Lowering impacts now

Concrete is already helping in the construction of buildings whose whole-life performance can offset the impact of their construction through superior energy efficiency and reduced maintenance requirements compared to other building products.

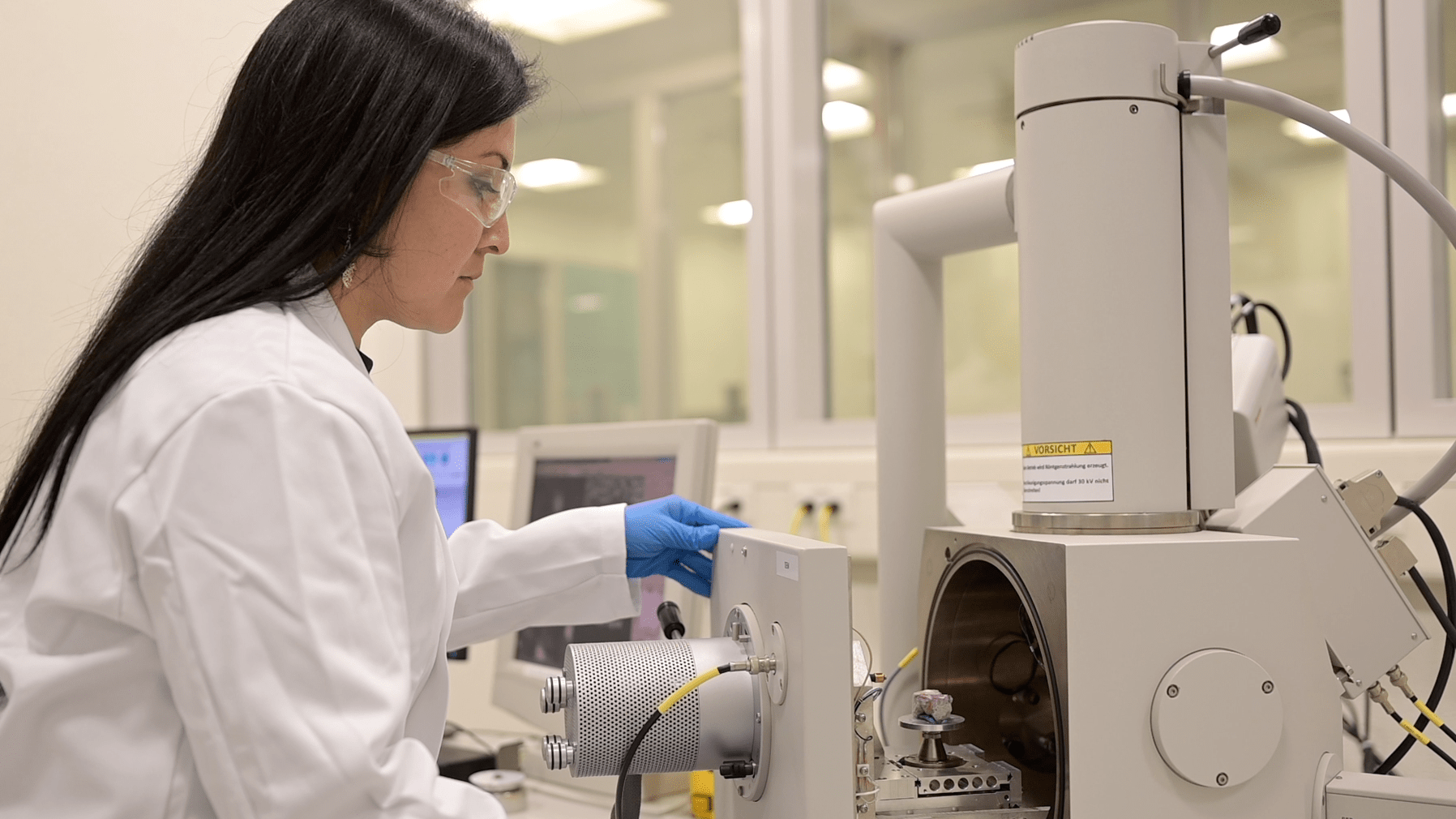

Clients, designers and specifiers can already reduce environmental impact by constructing buildings and homes using low-carbon concretes that have a lower clinker content. Secondary cementitious materials such as fly ash, ground granulated blast-furnish slag (GGBS) and limestone reduce embodied carbon because they can be used in combination with smaller amounts of Portland cement.

Significant product and manufacturing innovation is taking place too. The Mineral Products Association (MPA) is currently working with Hanson Cement, Forterra Building Products, and the Building Research Establishment (BRE) to develop, test and demonstrate low-carbon multi-component cements. Some of these new cements have 55% lower embodied carbon-dioxide equivalent than Cem1.

In partnership with the UK Department for Business, Energy & Industrial Strategy (BEIS), the MPA is trialling innovative kiln fuel mixes involving biomass, hydrogen and plasma technology to reduce carbon emissions through switching from fossil fuels in cement production.

Circular economy

Building with concrete can help to support a circular economy in which more buildings have a longer life cycle and can be reused rather than be demolished. This is because concrete structures have a long lifespan, reduce maintenance needs, offer greater fire protection and resistance to water escape and flooding compared to materials such as timber. They enhance energy efficiency through the use of thermal mass and can be reconfigured multiple times, if necessary, throughout their lifetimes.

When it comes to the end of life concrete also provides certainty. Instead of giving up its CO2 like other products it is 100% recyclable and can be crushed for reuse as a quality aggregate or used as a recycled aggregate in new concrete.

No matter which industry you operate in, net zero doesn't come with a set of instructions. We all know the government's net-zero carbon 2050 target, but each sector will achieve that in a different way.

It seems clear that we are at a turning point and the consequences of decisions we make now will have a profound effect on the future. And so, along the journey to net zero, we all have a responsibility to focus on facts, data and not rhetoric or perception about concrete or any other construction product. In this way, we can all be sure we're making the best decisions.

Sustainable statistics

In addition to the significant progress reducing carbon emissions, the concrete and cement industry has made progress in other areas as part of its ongoing efforts to improve its sustainability performance.

- Concrete is a locally produced material with an established, national supply chain – the average delivery distance for ready-mixed concrete is only 12km.

- More than 95% of UK concrete is produced domestically; by comparison, 67% of timber and 60% of steel used in construction is imported.

- More than 90% of UK concrete is certified as 'very good' or 'excellent' under the BES 6001 Responsible Sourcing of Construction Products framework.

- Concrete is 100% recyclable. 90% of hard construction and demolition waste is recycled as aggregates.

- The industry is a net consumer of waste, using more than 200 times more waste and by-products from other industries than the waste it sends to landfill.

Chris Leese is director of UK Concrete

Contact Chris: Email | Linkedin | Twitter

Related competencies include: Legal/regulatory compliance, Minerals management, Sustainability