_Steve_Wilson.jpg)

In the UK, parts of all the major coalfields have in the past been affected at some time by surface emissions of mine gas. The issue came to the fore after mine gas was found to be seeping into recently built houses in Gorebridge, Scotland and a decision was made to demolish them in 2017. Incidents caused by mine gas emissions are rare but nonetheless there are important lessons to be learned from the Gorebridge situation.

A study by the United Nations Economic Commission for Europe in 2019 found that not all colliery closures necessarily lead to gas emission. During the 1990s an average of about 3 new incidents per year were reported, of which more than 60% were attributed to leakages of gas through old, abandoned mine entries. While methane ignitions have occurred in residential buildings, there have been no fatalities. In contrast, blackdamp (carbon dioxide and nitrogen or oxygen-deficient air) emissions have led to a number of deaths.

Mining statistics

- 1947–1998: more than 900 deep mines closed in the UK

- 75 surface gas emission incidents were recorded

- 1990s: average of 3 incidents per year reported

The Scottish government researched incidents related to carbon dioxide emissions from old mines. The data summarised in Figures 1 and 2 shows that where the source or pathway for the gas was stated it was either related to shafts – or other entries – or shallow coal workings. None of the incidents was caused by carbon dioxide emissions from old deep mines through the ground above.

.jpg)

.jpg)

There is clearly a risk associated with mine gas emissions in certain situations, but not all areas of a former coalfield are a risk. The key factors that indicate an elevated risk of mine gas emissions are the presence of former mine entries, faulting and/or shallow mine workings below a site. An understanding of how coal mining methods have developed over time is vital when assessing the potential risk of mine gas emissions.

Coal mining methods

Surface outcrops: this is how early coal mining in the UK started on a small scale. It gradually followed the seam deeper into the ground using short tunnels known as adits driven into hillsides, sides of river valleys or slopes. The length and depth of these entries was limited by lack of ventilation and roof support. These early workings predate any record keeping of mine workings. Bell pits were used from the thirteenth or fourteenth century to gain access to deeper seams. Bell pits were formed by digging a shaft of 1m to 1.3m diameter down to the coal seam. Coal was then dug out from around the bottom of the shaft resulting in a bell-shaped excavation. There may often be a series of bell pits parallel and close to the seam outcrop but they rarely exceed 12m depth. Again, these would not have been recorded. The further from the outcrop and deeper the seam the less likely it is that shallow workings will be present.

Shafts: were used to reach deeper coal horizons from about the middle of the 16th century. These early shafts were still relatively shallow and were not recorded. At first single shafts were used but later two or more shafts were constructed for ventilation. By the end of the eighteenth century some shafts had been constructed up to 250m deep with a diameter of 4m. Some modern shafts extend to depths of 1,000m.

Room and pillar workings: originally developed to allow extension of bell pits, they rarely extend more than 40m from a shaft. The excavations to remove coal were supported by pillars of unmined coal. Over time the distance from the bell pit or shaft and the depth increased. The layout was arbitrary at first but became more systematic, with later workings having distinct rectilinear patterns. Pillar robbing – removing the coal – at the end of mining operations was common but this method is not common in more recent deep coal mines.

Longwall mining: was the process used for most deep mining in the UK. This involves a coal face – the longwall – that is up to 300m long and accessed by roadways perpendicular to it. The coal face area is supported temporarily and as the works advance the roof behind is allowed to collapse to leave an area of waste.

Surface or opencast mining: involves extracting coal by stripping off the covering soils to expose the seams in effective quarrying for coal.

Figure 3 shows the various mining methods used in the UK.

Rising groundwater can cause increased mine gas emissions but in many parts of UK coalfields groundwater levels are recovered and/or are maintained at stable levels. Mine gas emissions that affect developments do not occur from permanently flooded deep workings, because the water constrains or prevents the processes that cause gas to be present in mine workings. The water also reduces or prevents gas migration out of the ground. Emissions through the ground from any deep workings will not be an issue if the overlying rock is greater than 150m deep unless faults are present, which can provide a pathway for gas to escape to the surface more easily.

.jpg)

Conceptual model

It is important that a gas risk assessment is based around a robust site-specific conceptual ground model. This is because gas monitoring results alone will not provide a reliable assessment of mine gas risk. One of the reasons for this is that carbon dioxide and reduced oxygen concentrations are widely present in soils and rocks across the UK even where there are no mine workings. The gas is produced by natural chemical and biological processes that occur at very slow rates. Although this produces concentrations of gas in monitoring wells it does not cause significant emission of gas from the ground. This is why depleted oxygen – less than 19.5% – in monitoring wells should not be used as an indicator that there is a risk of mine gas emissions.

To develop a conceptual model for mine gas risk you should do thorough desk research to collect information about a site followed by interpretation of the data. The first place to look for information about mine gas risk is the Coal Authority online interactive viewer. The information on the British Geological Survey geological maps and online borehole scans shows known mine entries, areas of seam outcrops and the likelihood that shallow workings are present. In the Durham and Northumberland fields it also includes data on groundwater recovery.

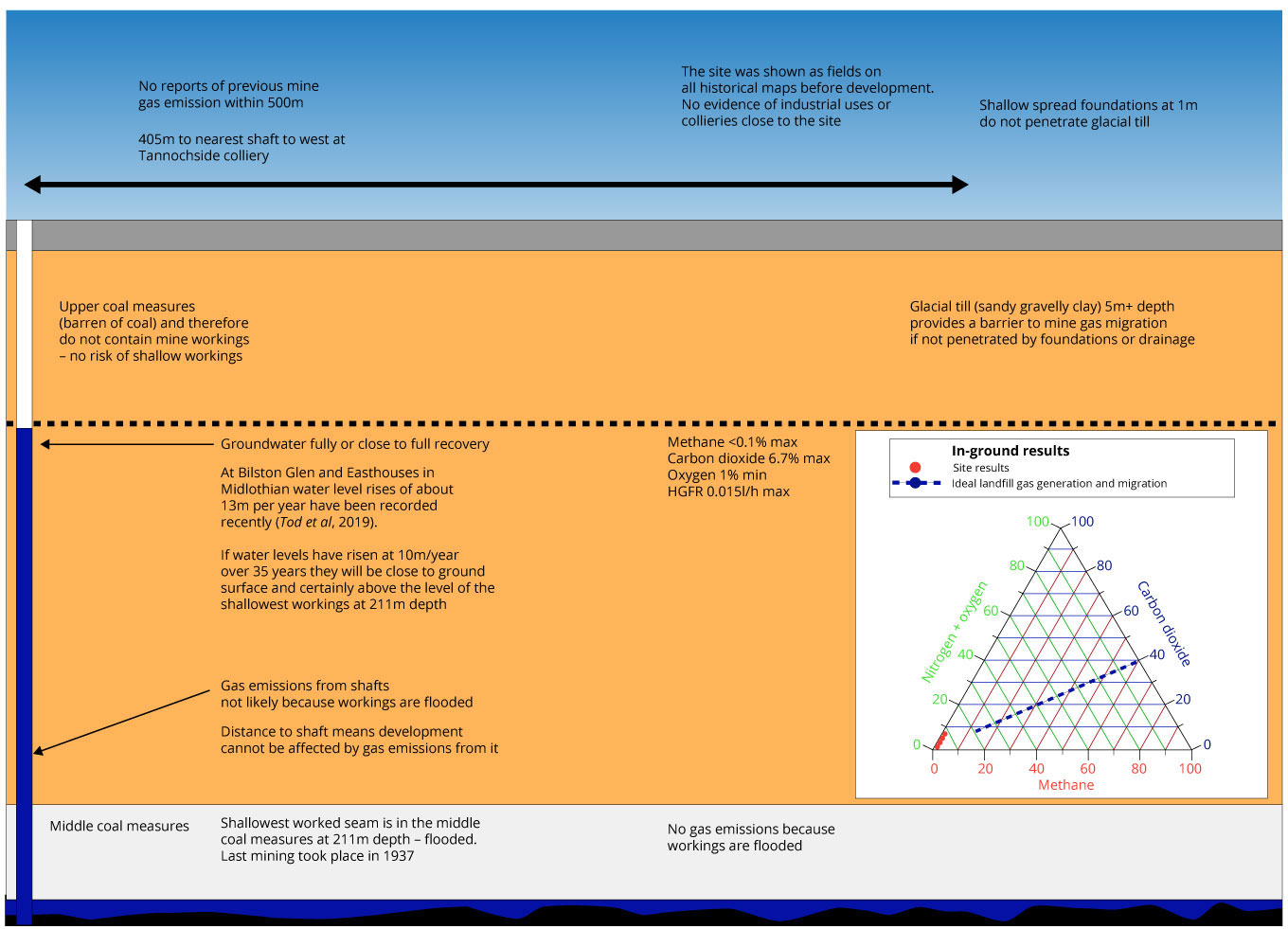

The conceptual model should be a geological cross-section that considers the source of gas and the likely pathway to the surface to reach a receptor. The model should be site-specific and not include generic statements such as ‘groundwater rises can push gas out of the ground’ unless they relate to that particular site. Mine entries and shallow unflooded workings overlain by fractured sandstone pose the greatest risk because large volumes of gas can be emitted in response to drops in atmospheric pressure. Deeper flooded workings with no nearby entries pose minimal risk. Figure 4 shows an example of a conceptual model that shows minimal risk of mine gas emissions. Of particular note on this site is the presence of the upper coal measures that did not contain workable coal seams in this area – referred to as barren – and thus there are no shallow workings.

Clients must be confident that anyone advising on mine gas risk possesses the right knowledge and skills and holds the relevant professional qualifications. Professional registration demonstrates that risk assessors have met the standard that gives the public, employers and their clients that confidence. One such scheme is the Society of Brownfield Risk Assessment (SoBRA) accreditation scheme for risk assessors (including ground gas, some of whom will have appropriate experience in mine gas risk assessment).

Mine gas can pose a significant risk to developments in certain circumstances. However, not all areas of coal fields will be affected. The main risk factors are proximity to mine entries and shallow unflooded workings with limited or no barrier, such as a clay layer above to prevent gas migration to the surface. A robust conceptual model allows interpretation of gas monitoring data. Gas concentrations in monitoring wells alone – especially depleted oxygen – should not be used as a risk indicator for mine gas.