In a brave new 5G world, where it takes less than three seconds to download a feature-length movie to a smartphone, the potential impact on construction projects is starting to excite tech-savvy professionals and turn heads in company board rooms.

More than a mere upgrade to 4G, the new network standard will deliver a 10-fold increase in data speeds, fast enough to stream detailed 3D BIM models, or access immersive virtual reality (VR) or augmented reality (AR) in the blink of an eye.

Increased bandwidth capacity and network slicing features will accommodate as many devices and applications as required, raising the prospect of fully connected construction sites or coordinated teams of automated robots.

Meanwhile, ultra-low latency – a key technology behind driverless cars – will make it much more viable to remotely control construction vehicles or plant equipment, potentially from thousands of miles away from the job site. This could support 24-7 operations and help keep programmes on track in a socially distanced post-COVID-19 world.

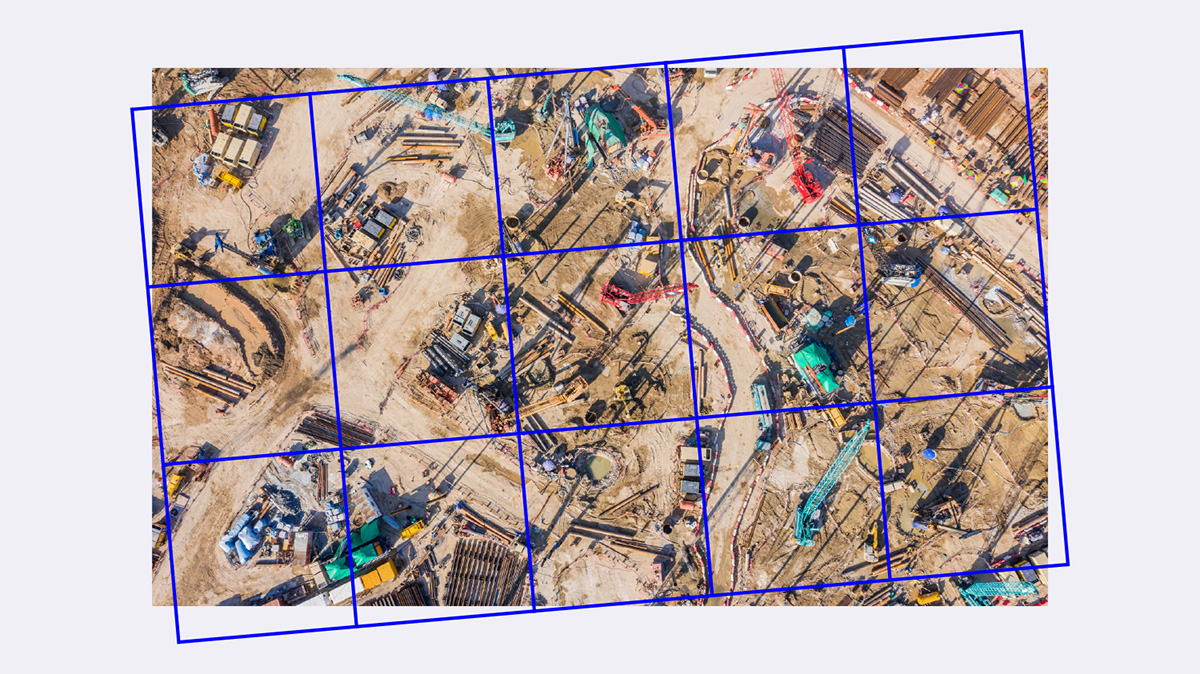

Keen to explore the opportunities, construction firms, telecoms operators and equipment makers have rolled out various prototypes and testbeds to explore possible use cases. Arguably the most advanced of these is China's first 5G smart construction site, located in the Beijing Economic-Technological Development, where disruptive tech such as artificial intelligence (AI), blockchain, and the internet of things (IoT) have come into play.

Robert Herman MRICS, a proptech expert and CEO of US 3D mapping company ReScan – an RICS Technology Affiliate Programme member – tells Modus: “Given the near real-time monitoring possibility of 5G, projects will be delivered faster and risks mitigated better by having clear end-to-end visibility and better quality assurance. The network standard will bring certain tech solutions within reach of SME contractors, for example visualisation using VR and AR will become highly accessible.”

But bold claims for the technology are countered by some barriers that may stifle uptake. 5G signals have difficulty getting through certain materials used in construction, and achieving proper coverage on remote or large sites may require significant investment in infrastructure. National rollouts have also been plagued by controversy, particularly in the US and in the UK, where the involvement of Chinese tech giant Huawei and concerns over data security and nation state interference have delayed investment in infrastructure.

“Given the near real-time monitoring possibility of 5G, projects will be delivered faster and risks mitigated better” Robert Herman MRICS, ReScan

Power up

The last decade has seen construction embrace digital like never before as teams increasingly turn to software for construction project management, scheduling and BIM to improve efficiency.

However, a focus on designers in the back office, rather than workers and managers at the coal face, where project delivery information is monitored and updated, has left the industry’s much maligned productivity gap wide open.

On-site connectivity issues are a big part of the problem. Contractors frequently handle large documents in the field, such as 3D models or sets of 2D drawings, but poor signal quality often leaves people twiddling their thumbs waiting for downloads.

5G promises to remove this problem by delivering data at speeds of up to 10Gb per second, 10 times faster than the fastest 4G connection. The supercharged connection should accelerate the transmission of large volumes of visual data consumed by projects, from time-lapse imagery, to laser scans and computer vision imagery used for security.

As Varun Kumar Reja, doctoral research scholar at IIT Madras in India, and an expert on 5G applications in construction, explains: “Assume a site produces around 300Gb of visual data each day. The upload time would be about 70 hours on a 4G network, but just 7 hours on a 5G network. This means the project manager will get the results overnight rather than having to wait two to three days for data to upload and process.”

Arguably the key differentiator for 5G is negligible latency (the lag between the moment you click on a button on screen and the moment the internet server hosting the software tells your app if you succeeded), which raises the prospect of real-time access to data in the field and a live link between site activities and the office.

This means BIM data could be captured and updated instantaneously, helping speed up project decision-making to address issues sooner.

“Reality capture data from on-site cameras and drones are already recorded and overlaid in BIM to compare the original design model with actual progress on site to spot any deficiencies, deviations and differences,” says Sherief Elabd, director for industry strategy and innovation in construction and engineering at Oracle. “5G can speed that up and allow for very quick analysis across the model. It could help BIM fulfil its role as the single source of truth on a project.”

The same technology could augment a project’s ability to track quality assurance and quality control issues, which often cause delays and cost overruns.

“5G could help BIM fulfil its role as the single source of truth on a project” Sherief Elabd, Oracle

Key enabler

Fifth-generation technology is seen by many as an enabler for existing data-intensive applications that have so far failed to reach a mainstream audience, such as immersive VR and AR, IoT or 360º video streaming.

SMEs are often excluded from innovation due to the high cost of investment, but 5G could bring some applications within their reach, says Herman: “Some solutions may be cost prohibitive to SMEs, but others don't require any up-front investment and will help tremendously with efficient and safe delivery, such as the cloud-based collaborative software platform HammerTech, or the virtual site walkthrough and construction documentation platform OnSiteIQ.”

5G could support the business case for wearables and other tech used to monitor worker health and safety, such as devices in hardhats that detect when workers enter restricted areas or come into close proximity with machinery, or computer vision cameras that monitor for PPE compliance.

The 5G construction site in Beijing, which being developed by China Construction Eighth Engineering Division, a subsidiary of China State Construction Engineering, has implemented a system to monitor the health of every worker. It measures 10 indicators, including blood pressure and electrocardiography, and issues physical examination reports. A security monitoring system exploits AI to check if people are wearing masks.

The low latency of 5G is critical to the success of driverless cars, and it has already laid the groundwork for the first unmanned and remotely operated machines in construction.

Contractors in China have developed a 5G-based system to power an unmanned fleet of road pavers and rollers to build the Panzhihua-Dali Highway between Sichuan and Dali provinces. According to state news agency Xinhua, the vehicles use GPS positioning systems, microwave communications, millimetre wave radar and other sensing equipment to understand their environment and are coordinated from a remote data centre.

Other pioneers in the field include South Korean conglomerate Doosan, which entered the record books last year when it operated an excavator in South Korea from 8,500km away, in Germany, over 5G.

But applying the technology poses issues, particularly around health and safety in such a dynamic and high-risk environment. Fully autonomous machines are unlikely to be viable on regular construction sites any time soon, although there may be a case for using remotely operated machines at night when workers have gone home, or in restricted areas, to boost productivity.

Herman comments: “We've been working with a Japanese company, which is using robots to move construction materials on site after hours. However, at present the possibilities are limited because the robots need bandwidth and constantly run into connection issues. With 5G you could have swarms of robots moving equipment and materials at night, so that in the morning, when construction workers return, everything is in the correct place and they can simply pick up the work.”

Divide and conquer

Mobile networks come under heavy strain as multiple applications and services create different demands on functionality and performance.

A unique feature of 5G will be its ability to route traffic intelligently to provide each user and application with a customised connection and slice of the network. This should allow construction sites to run multiple applications with different frequency and bandwidth requirements, ranging from streaming video to IoT, without encountering any issues.

“The ability to slice up the network is quite important,” says Jefferson Wang, global 5G strategy lead at Accenture. “Some projects could use a private network to route sensitive information they don't want to leave the site, such as tracking data on workers, their location on the construction site, how close they are to dangerous equipment etc. You might not want that data floating through the pipes of a public network.”

Jittery start

Fifth-generation mobile promises to transform the way individuals and businesses interact with technology, but certain technical, economic, political and cultural barriers could prevent it from making a meaningful connection with construction.

Network infrastructure, including cell tower masts and small cell nodes on buildings and lamp posts, has started to appear in cities, but it may be years before coverage is comprehensive and speeds are fast enough for the most innovative use cases. The fastest 10Gbps connections require direct line of sight, yet materials regularly used in construction, such as concrete, treated glass and steel, block out high-frequency signals.

Projects in remote or rural areas, where networks aren't likely to arrive for years, will have to invest in their own infrastructure, which could prove very costly because 5G relies on a larger number of small antennas spaced closer together than 4G.

A reliance on international equipment vendors to meet national governments’ rollout targets for 5G has raised concerns over the potential for nation state interference. Huawei is being required to remove its 5G kit from the UK network by 2027, a move that will delay the network rollout. Similar bans are in place in Australia and New Zealand and the US has slapped sanctions on the Chinese firm to reduce its ability to source components and technologies from US companies.

Impressive new technological capabilities always generate hype, but understanding of the most practical and cost-effective use cases for 5G remain elusive, says Wang. “We have to ask ourselves if we are solving a problem that matters? The use cases that currently appear to stack up are those that already exist and could benefit from faster connections [see boxout]. For example, applications for onsite monitoring of worker health and safety and location, using high-resolution drone imagery that feeds into BIM, site security and monitoring.”

Andrew Knight, international data standards director at RICS, points out, “The profession will need, in my view, to upskill around the use of AR/VR, AI, Big Data etc., so as to work with and source these applications from vendors, and to work with data scientists/analysts to ensure that the ‘machine is correct’.”

With many organisations still lacking a standard approach to project delivery, and with huge amounts of data being captured but not used, it may be a case of first learning to walk before we can run.

“We have to ask ourselves if we are solving a problem that matters? The use cases that stack up are those that already exist and could benefit from faster connections” Jefferson Wang, Accenture

HoloLens 2 Microsoft’s augmented reality headset overlays virtual information on to a live view of the real world. 5G may prove instrumental to bringing it, and similar systems such as Magic Leap, into mainstream use. |

Dusty Robotics The robotic site layout system synchronises with designs in BIM, a wide bandwidth network could enable multiple robots to connect simultaneously without losing signal. |

Digital twins Virtual replicas of buildings and infrastructure could hugely benefit from a real-time, lag-free 5G connection to internet of things sensors, helping designers and engineers understand how assets perform and how they could perform better in the future. |

Holobuilder The construction progress management platform uses a mobile app to capture 360° progress photos of a site and create remote virtual walkthroughs. A super-fast connection could speed up the capture process and deliver more frequent walkthroughs to keep tighter control of any issues. |

HTC Vive VR software that runs on goggles like the Vive can suffer from network lag, leading to motion sickness and less-immersive experiences. The next-generation network could resolve these issues and enable large teams to connect and meet inside virtual models. |

Five products and platforms that could benefit from a 5G connection

HoloLens 2 Microsoft’s augmented reality headset overlays virtual information on to a live view of the real world. 5G may prove instrumental to bringing it, and similar systems such as Magic Leap, into mainstream use. |

Dusty Robotics The robotic site layout system synchronises with designs in BIM, a wide bandwidth network could enable multiple robots to connect simultaneously without losing signal. |

Digital twins Virtual replicas of buildings and infrastructure could hugely benefit from a real-time, lag-free 5G connection to internet of things sensors, helping designers and engineers understand how assets perform and how they could perform better in the future. |

Holobuilder The construction progress management platform uses a mobile app to capture 360° progress photos of a site and create remote virtual walkthroughs. A super-fast connection could speed up the capture process and deliver more frequent walkthroughs to keep tighter control of any issues. |

HTC Vive VR software that runs on goggles like the Vive can suffer from network lag, leading to motion sickness and less-immersive experiences. The next-generation network could resolve these issues and enable large teams to connect and meet inside virtual models. |

RICS has published an insight paper on the future of BIM and the digital transformation of the construction and infrastructure sector, which discusses how the technology has evolved, and the need for surveyors to explore its potential. The paper can be found here.