Preston bus station multi-storey car park contains steel at risk of corrosion © CPT

An increasing number of reinforced concrete, masonry-clad steel-framed structures from the 20th century are being listed. However, the embedded steel elements of such structures are vulnerable to corrosion.

It is therefore imperative that surveyors who work in the heritage sector understand corrosion processes, and the options available to manage this risk.

While steel in fresh concrete is passive – with the alkalinity of the concrete and the typical lack of aggressive ions in the pores meaning it stays stable and does not corrode – the reaction of the concrete with carbon dioxide in the concrete's pores or carbonation can over time reduce alkalinity.

Chloride ions – typically from salt or the liberation of chlorides cast into the concrete – can also interfere with the steel's passivity. Either put the steel at risk of corrosion.

These processes can be seen in two structures that may seem completely different but both contain steel threatened by corrosion.

In the North West of England, Preston bus station's multi-storey car park was at risk due to contamination of reinforced concrete elements by salt used to de-ice roads, while in the North East, Bamburgh Castle was affected by the presence of chloride-contaminated aggregates, combined with carbonation of the concrete surrounding the embedded steel floor beams.

De-icing salt ingress and unprotected patch repairs

Inspired by the Temple Street parking garage in New Haven, Connecticut, the Preston car park is more reminiscent of an airport terminal than a traditional bus station.

The sweeping, ribbed structure with curved parapets measures almost 200m, with 80 individual bus bays, and is of a style that is seen by some as the epitome of brutalist architecture. At the time of construction in the late 1960s, it was the largest bus station in Europe.

When Concrete Preservation Technologies (CPT) was asked to inspect the structure, the corrosion issues were clear, with the many patch repairs and spalls due to salt ingress leading to corrosion which expands to crack the concrete.

The area around patch repairs in reinforced concrete often fails within five years because of the electrochemical differences between the old and new concrete accelerating corrosion in the material surrounding the patch. This is called the incipient anode effect.

We tested the car park using half-cell potential mapping, a technique that measures the corrosion risk of steel in a structure using ASTM 876 and RILEM TC 154-EMC as guidance.

These results were overlaid with carbonation depth and chloride ion tests at sample locations, to correlate the risk with the cause.

The results painted a clear pattern of corrosion hot spots throughout the decks, showing that de-icing salts on the tyres of cars during the winter months were likely to blame. This data was then used to generate a bespoke strategy for the high- and low-risk zones.

Anodes installed to protect the steel

CPT decided to protect the high-risk areas with DuoGuard, while patch repairs in lower-risk areas were to be protected from the incipient anode effect by the installation of PatchGuard.

DuoGuard is a hybrid anode system installed into 30mm-wide holes in the car park deck. Initially, the anodes used an external power source for around a week to pass large currents and halt all ongoing corrosion, then connected directly to the steel as galvanic anodes.

Galvanic anodes are made from activated zinc, which, when connected with steel, creates a cell or battery. This provides a protective current, with the zinc corroding sacrificially.

As a result, every time there is an increase in corrosion risk from heat or moisture the zinc will corrode faster and provide a larger protective current. The advantages of these systems are that they are self-powered, reactive and require no ongoing maintenance.

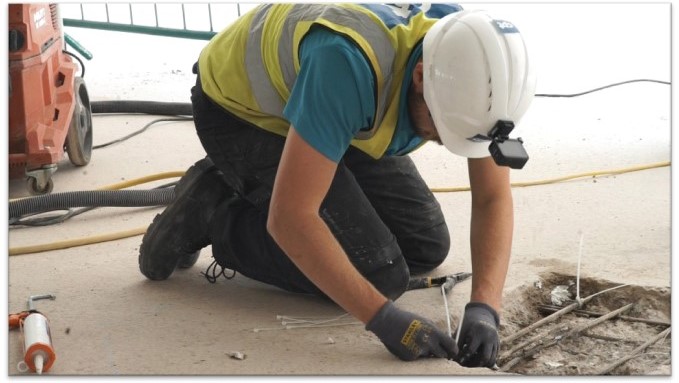

PatchGuard anodes were chosen for installation around the perimeter of all patches in the concrete deck where cracking or spalling had occurred. These small anodes are installed into 25mm holes drilled in the perimeter of the patch.

Like DuoGuard, these anodes are galvanic and made from activated zinc, surrounded by a proprietary putty that keeps it wet and activated. When connected to the steel they provide a current and protect the surrounding steel. These systems also require no maintenance, allowing for the ongoing protection of the steel around the patch from corrosion for their design life.

'Hybrid anode systems are self-powered, reactive and require no ongoing maintenance'

PatchGuard anode installation © CPT

Data from the car park after the anodes were commissioned indicates that they very quickly reduced the corrosion rate of the steel to levels that are seen as low-risk or passive.

Both types of anode will continue to provide protective current to the structure, responding to any corrosion threats by increasing protection during times of increased temperature, moisture and ion ingress that may arise and adapting to changing environments.

Management system redresses damage to castle

Bamburgh Castle was constructed almost 1,000 years ago, with the Norman core built on top of a much older structure on a protrusion of volcanic rock. Over the past millennium, it has been added to, altered and amended to fit the region's needs and its private residents.

One of the 20th-century alterations was the addition of new floors in the clock tower. These were formed using steel I-beams – so-called because they are shaped like a capital I with serifs – with hollow terracotta pots making a formwork over which concrete was poured.

This novel building method encased the majority of the steel beam in ageing concrete, leaving the underside of the steel flange exposed and later coated only with plaster.

When CPT was called in to inspect the floors, we found corrosion of the steel. Because the products of corrosion expand, a management system was required to prevent damage to the structure.

The aesthetics of heritage structures are paramount, and any system chosen must have little impact on the historic clock tower rooms, and work with the existing structure.

The most important factors when considering what approach would be appropriate were the lack of depth in the concrete, the ability to monitor the corrosion rate using a minimally intrusive junction box, and the need to install the system through the terracotta formwork from the underside of the floor.

A DuoGuard system was chosen, combined with an appropriate anti-corrosion coating on the lower flange of the steel. The system features anodes of several sizes, allowing for an appropriately sized unit to be selected.

The anodes were installed through cored holes in the soffit of the terracotta and all wires were routed through the hollow formwork, reducing the need to cut chases to house them.

Reference electrodes were installed to measure the local steel potentials, and sub-zones were created to measure local corrosion rates. As at the Preston car park, the system was externally powered for one week, after which the corrosion rates had fallen to levels that are considered low-risk or passive.

The system requires no permanent external power supply and all connections are housed in small, discreetly located junction boxes, enabling access to monitor steel corrosion rates and corrosion risk, as well as potential repowering of the system in future if necessary.

Holes cored through the render and terracotta pots for anode installation © CPT

Range of buildings benefit from corrosion prevention

Hybrid and galvanic anodes, such as DuoGuard and PatchGuard respectively, are now widely accepted as a proven way to prevent corrosion in a range of structures and buildings.

Corrosion is one of the major causes of structural decay in steel-framed and reinforced concrete structures. The surveying of corrosion is a specialised field with ISO 15257 level 2 and level 3 trained-specialists available to assist in the surveying of structures, as well as give recommendations and work with experts.

These experts can help extend the life of repairs and structures using robust galvanic and hybrid systems in a way that minimises long-term cost and preserves these structures for the future.

In addition to those featured in this article, other recent examples of anode installation carried out by CPT include the steel-framed Shelbourne Hotel in Dublin, Levita House residential block in the London Borough of Camden, the Art Deco Berkeley Hotel swimming pool in London and the four-storey neoclassical Stormont Parliament Buildings in Belfast.