© Richard Fitton

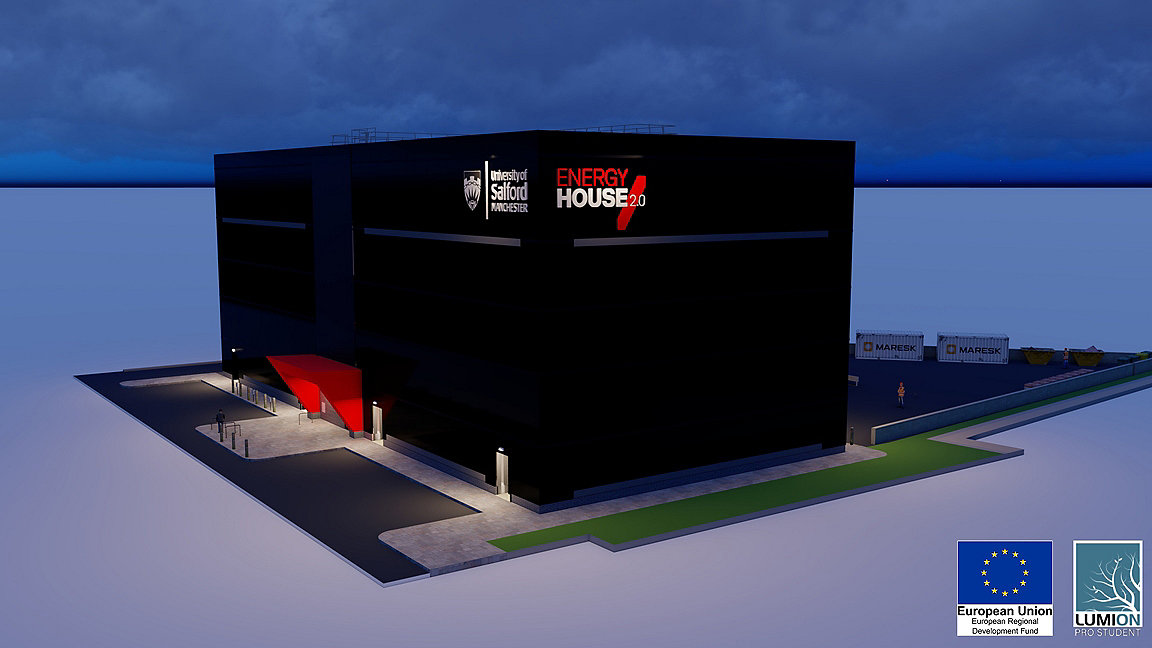

Construction of Energy House 2.0 (EH2) is now under way in Salford. The project is designed to provide a research facility where whole buildings can be constructed and tested in a controlled environment.

This £16m project, part-funded by the European Regional Development Agency, will explore the future of the UK's new and existing homes. The facility's 2 large environmental chambers will be able to replicate the weather experienced by 95% of the world's population, and testing in these conditions will help us understand the performance of products and systems, digital services, and whole buildings.

This article will explore the detailed design of the project and its objectives; but first we will look at the context for its development.

Energy policy context

The energy performance of our buildings is a major policy issue. The role of housing in the decarbonisation of the energy system was highlighted by the UK government in its 10-point plan for a green industrial revolution launched in November 2020, and expanded on in the energy white paper, Powering our net-zero future.

As housing accounts for 19% of UK carbon dioxide emissions, the white paper proposes a more integrated energy system and built environment. In the short term, our homes and transport will be electrified, with hydrogen used as a replacement for gas and low-carbon district heating following in the medium term.

Digitisation of the energy system will also allow householders to access complex energy services, linking smart meter infrastructure to batteries, renewables, heating systems and the wider electricity network. The demand for higher-performing new buildings, as required by the Future Homes Standard, will oblige developers to adopt modern methods of construction (MMC) to ensure much higher levels of building performance.

Meanwhile the government's Clean Growth Strategy identifies the economic benefits of new, low-carbon products and services. For example, retrofitting our existing housing stock to improve its energy efficiency could create an estimated 80,000 jobs annually between 2025 and 2028.

The need for EH2

The role of EH2 in supporting these agendas was highlighted by Greater Manchester's mayor Andy Burnham at the November launch of the project's construction phase.

He said: "A key part of meeting Greater Manchester's target to be carbon-neutral by 2038 is in reducing emissions from our homes. We need our buildings to become more energy-efficient and use renewable energy more effectively, and EH2 will help us define how to achieve this. The facilities on offer are unique in the UK, and will help businesses to test new equipment and mechanisms to reduce carbon emissions."

The project builds on lessons from the Salford Energy House, which was launched in 2011. At the time this was a world-first, designed to research products and systems by retrofitting them on an entire Victorian property under controlled conditions and testing their performance.

However, the original Energy House has its limitations. As it represents only 20% of UK stock, it means new forms of construction or international archetypes cannot be tested. At the end of any experiment, it must always be returned to its existing conditions as well, so it is impossible to test any improvement that cannot be wholly removed.

The scale of the chambers has also meant that some elements, such as airflow, cannot be fully replicated. Finally, because of the unique nature of the facility, many partners have had to wait several months to access the Energy House due to demand. Although the original house will continue to run – the property still has a role to play in testing retrofits, and serves as a baseline for a lot of research – EH2 has been specifically designed to respond to the issues this first house faced.

Climate simulation

Building on the principles of the original house, EH2 extends them in several ways. It will have 2 chambers rather than 1, each of which will be large enough to accommodate 2 starter homes, making a total of 4 test properties.

The project will be able to simulate a greater temperature range, as well as wind, rain, snow and solar radiation, replicating the weather of 95% of the world's populated land mass.

Both chambers will have large, well-insulated cargo doors to enable access for construction traffic and building materials, which will allow construction of modular buildings. Given the size of the chambers and their flexibility, we have also been approached by manufacturers of products such as cars, sleeper rigs, caravans and emergency shelters looking to understand their products' environmental and energy performance.

Complex HVAC requirements

The central core of the project between the 2 chambers will contain the heating, ventilation and air conditioning (HVAC) equipment used to simulate weather conditions, as well as including office facilities and the control room.

The HVAC is by far the most complex and expensive part of the build. The original Energy House included a smaller system, but it was a unique project and there was a steep learning curve in commissioning it. Several amendments to the installed systems were necessary to maintain the steady temperature profile that would allow for scientifically valid repeatable testing.

This experience helped us design the extremely complex HVAC systems for the new facility, which will be able to create temperatures from -20C to 40C with an accuracy of 0.5C, while also controlling relative humidity across this range with a 5% margin of error.

The need to simulate the wide range of weather conditions takes a substantial amount of creative HVAC design. A packaged chiller system was selected for a robust, accurate and energy-efficient performance – which is important, given that it may be running 24 hours a day, 365 days a year.

Air passing into either of the chambers is chilled or heated by the HVAC beforehand. It is then fed into the chamber through a series of grilles at low level, with heat subsequently extracted by high-level ductwork after it has risen. It then re-enters the HVAC system again to be heated or cooled.

This approach is known as displacement ventilation, and ensures a low air velocity in the chamber so energy performance results are accurate – air movement over structures can have a significant effect on their heat loss, and the greater the flow around a structure the more heat will be lost. We need to control this to mimic the climates that we are studying. Furthermore, the greater the airflow the more inefficient the system will be, and the HVAC and ductwork would then need to be larger and thus more expensive.

Extensive sensor network

Because EH2 will be a building physics laboratory, data collection is central. As such, one of the main investments other than build costs is for the extensive sensor network to be installed.

This will see around 1,000 data points being collected on a minute-by-minute basis, all coming back to a central server where researchers will analyse energy performance, thermal comfort, thermal capacity, air permeability and a wide range of other metrics. To do this, power, temperature, heat flux and airflow must be monitored throughout the chamber and in the homes.

A further development from the original facility is the inclusion of pits in each chamber that are large and deep enough to build foundations for the homes in soil conditioned at the same ambient temperatures as the chamber air. If these were built in contact with the earth below the chambers, it would not be possible to collect realistic data.

"One of the main investments other than build costs is for the extensive sensor network to be installed"

The building itself will be relatively straightforward in terms of construction, with a steel frame and highly insulated cladding, similar to that found in cold storage facilities, and low air permeability. The piles are already in place, and the concrete bases of the test chambers are being poured.

Major housing shifts to be studied

The early projects proposed for EH2 are designed to address 2 major shifts in our housing stock. One is the introduction of MMC for new-build housing. When compared to traditional buildings constructed on site, the quality and tolerances of off-site manufacturing can, in principle, improve energy efficiency and internal comfort to a significant degree.

However, given what we know about the difference between modelled and actual performance – the so-called performance gap – EH2 presents an ideal opportunity to collect evidence, and consider related issues such as overheating, air quality and acoustics.

The second main issue relates to the planned, large-scale deployment of smart meters, electric vehicles, batteries and renewables, which means our homes may no longer be simply passive consumers, but active participants in the system, generating, storing and trading energy.

Both new and existing homes will therefore be very different. The role of EH2 is to make sure that lessons can be learned about the issues of designing, constructing and operating these future homes, which can be passed on to product manufacturers, developers, constructors, installers and occupants.

As the project develops, Built Environment Journal will provide regular updates on progress. The facility and wider research team are gearing up to work with partners on the housing issues of tomorrow. As an industry we need to collaborate to develop and maintain good-quality, low-carbon, high-performance housing stock.

Related competencies include: Construction technology and environmental services, Sustainability