Crop robotics are coming soon to a farm near you. Retrofit kits to convert conventional equipment for autonomous use are already being marketed in several countries. In the next few years several UK start-up companies have plans to commercialise robots designed for farm use. Those robots have the potential to change the management of rural land in the UK.

With tractors, combine harvesters and other conventional mechanisation, the economic rule of thumb is that bigger is better – but when human operators are removed from the equation the need for ever-larger equipment almost disappears. On the farm of the future, crop operations are likely to be accomplished by a swarm of smaller machines on small irregularly shaped fields, with woods, wetlands and other non-arable areas being farmed by robots almost as efficiently as large, flat, rectangular fields.

This large-scale shift to autonomous crop equipment is poised to occur in the next five to ten years. Most major farm equipment companies have autonomous equipment research and development programmes, and there are some 45 start-up companies around the world focusing on robotic farm technology. A kit to convert conventional equipment to autonomous use is already being marketed in the USA. The transition to crop robotics will create demand from landowners, farm tenants and farming enterprises for advice on how best to adapt their businesses; for example, tenancy agreements will need to be modified to reflect changing costs and production potential.

"This large-scale shift to autonomous crop equipment is poised to occur in the next five to ten years"

The new agricultural revolution

The Hands-Free Hectare (HFH) project at Harper Adams University has shown that it is technically possible to produce arable crops in the UK with autonomous machines.

- The farmland price premium for large flat rectangular fields will be reduced because small robots can farm small irregularly shaped fields efficiently.

- Small robots put less weight on the soil than large equipment which means less soil compaction better soil health and potentially more days for field operations because small machines may work when soils are too wet for conventional equipment.

- There will be an increase in hedges copses unfarmed sandy patches and other natural areas that provide habitat for wildlife and predatory insects as the capacity of robot swarms to farm efficiently around these areas allows more ecological balance.

- Weeding robots use lasers electrical weed zapping and mechanical control potentially reducing the need for pesticides which makes profitable organic crop production more feasible.

- Farming in peri-urban areas will be possible because of reduced reliance on pesticides and the smaller equipment that can be moved from field to field more easily in heavy traffic.

- Farming with robots can reduce production costs increase yields and adapt practices to accommodate consumer preferences.

HFH uses conventional small- and medium-scale farm equipment retrofitted for autonomous operation. Starting with a flat, square, 1ha field on Harper Adams University farm in 2017, two years later it was scaled up to a 35ha hands-free farm that will test the equipment under typical UK agricultural conditions. Until HFH, little public data has been collected on the farm management implication of crop robotics. Although several agribusinesses are developing autonomous equipment, their data is proprietary, while many universities and research institutes worldwide with prototype crop robots have little experience producing crops at a commercial scale.

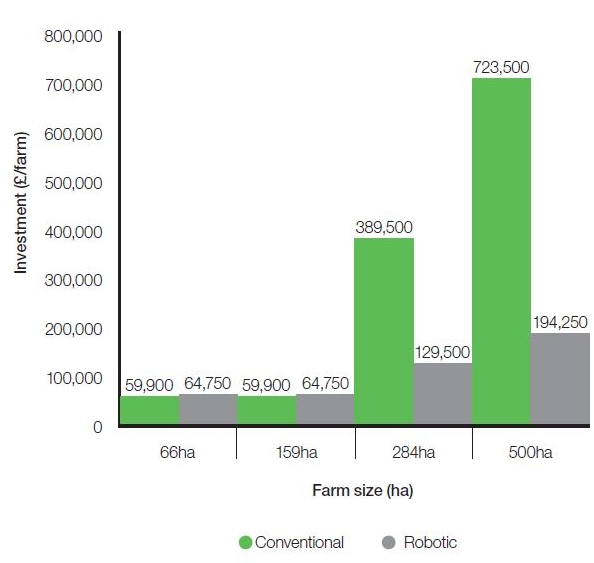

In contrast, the costs and returns from an HFH-type farming system are relatively easy to estimate. Because HFH uses retrofitted conventional farm equipment, the cost, reliability, repair expense, useful life and other machine characteristics are well known. HFH documented retrofit costs based on commercial global navigation satellite systems (GNSS) guidance and modified open-source drone software. The input requirements, field operations and yields for the commercial crops produced are also well documented.

- farmers own rather than lease or rent the robotic equipment

- human supervision of the autonomous equipment can be done remotely, for instance by checking a mobile app, rather than requiring the physical presence of a human operator in the field

- insurance costs and conditions for the robotic farm are comparable to conventional farms.

As the hands-free farm expands and provides new information, the research team plans to refine this analysis to examine the impact of field size, shape and topography, extend the analysis to assess a broader range of farm sizes and crops, and consider the impact of automation for larger-scale equipment.

James Lowenberg-DeBoer is professor and the Elizabeth Creak chair of agri-tech applied economics and Simon Keeble is chartered surveyor and senior lecturer at Harper Adams University

jlowenberg-deboer@harper-adams.ac.uk

skeeble@harper-adams.ac.uk

Related competencies include: Agriculture, Big data, GIS (geographical information services)