Image © Holly Challinor

James Lloyd-Jones talks to Sian Morgan about the growing business of vertical hydroponics.

Q: How did the idea of getting into vertical farming come about?

JLJ: When I was seven, I was watching Tomorrow's World and I saw a feature about hydroponics. That stayed with me for 21 years. Id been researching it when, after doing various jobs and being in business, I thought: why don't we actually do it?

I flew to Japan in January 2017 with a view to bringing the Japanese hydroponic growing technology back to the UK. But I could see weaknesses in the Japanese hydroponics system. I thought I could do better. As they had been the first to market, I learned from them and made changes.

A number of vertical farming companies have started and failed because they did not understand the energy and employment costs involved – hiring lots of people and trying to build consumer brands. We began on a business-to-business basis to prove we were competitive and could deal with quantity, and we took a look at the automation and the energy side. It takes a lot of time and effort to make sure that we can crack those issues to bring down our operating costs, including energy.

Q: How is vertical different to traditional farming? What type of crops can be grown? Do they have to be high value to make the operation financially viable?

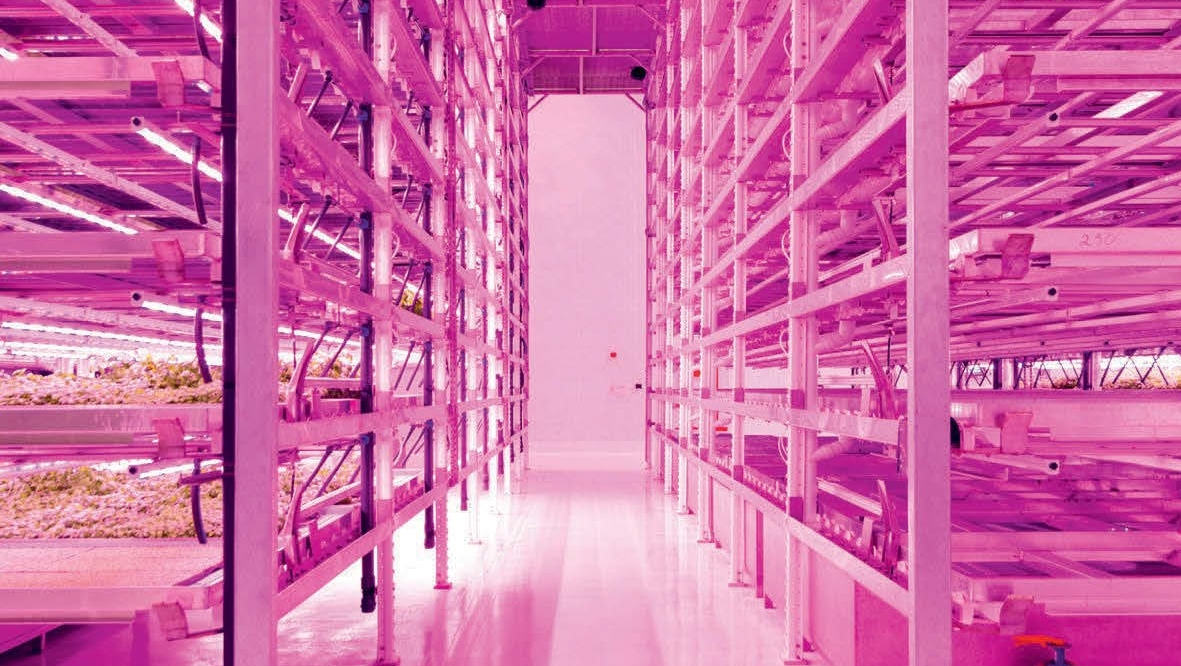

JLJ: The farm is stacked, so we have more than 17 layers in a 5,000m2 enclosed environment with no sunlight, using recycled water, employing fewer people than traditional farming. Food grown indoors in a clean environment has no seasons, is more sustainable, and we use fully automated machines that work 365 days a year.

At the moment, because vertical farming is in its infancy and just starting to be commercially viable, we grow highly perishable plants, such as herbs. But there's a move to grow different crops with a high nutritional value. It's easier for us to have a smaller carbon footprint than traditional farming because we don't have a conventional supply chain.

Q: Where is hydroponics happening? Where does it work best?

JLJ: Hydroponics will work anywhere around the world and has even been used in space, but I think it works best in harsher climates such as Australia, the USA and Russia for instance, where food is often moved around in trucks.

Q: How does the business work? Are the premises bought or leased?

JLJ: We own them. We are old-fashioned like that, we prefer owning stuff. And now we are planning to expand. Ocado bought into us not long ago and took a 58 per cent stake, and we've got expansion plans for two more facilities in the UK. There's been a lot of interest internationally in using our technology and building up the business around the world.

Q: What are the challenges of being a start-up hydroponics company?

JLJ: Initially, there's the high capital expenditure, but we're working hard to bring these costs down. And we're learning more all the time. Vertical farming is a whole different ball game to using a container to grow, which some companies have tried. Electricity is our biggest cost, so we've moved to use as many renewable sources and assets as we can own and operate ourselves. We are heading towards full carbon neutrality, and that also protects our electricity costs because we own the energy assets that supply us.

Q: How is your Scunthorpe operation different to other indoor farms?

JLJ: First, we try to build as much growing area from the UK supply chain as we can. We've done everything on a budget but now we have a bit more headroom. The other thing is that we are a high-care facility, so everyone who goes in and out has to go through the same sort of quality assurance protocols as in, say, a microchip factory, before they're allowed in or out. We believe we're the largest such high-care growing facility in the world at the moment.

Q: What percentage of food is being produced in this way in the UK, or elsewhere in the world?

JLJ: I'd estimate it's less than one per cent, so there's huge potential for growth. I think in the next ten years we will overtake and eclipse greenhouse growing, which uses land inefficiently because it needs so much space and takes a lot of labour on a single layer of crop over huge distances.

Q: What is the optimum scale for hydroponics?

JLJ: The bigger the better, so about 20,000m2 would be a good size.

Q: What do you think are the implications for land use?

JLJ: In the current market, there are a lot of older, redundant commercial properties that are taking a lot longer to rent or sell. They could be reconditioned and used for hydroponics – it's not easy, but its achievable. I think you'll start to see far bigger units near joint or mixed-use sites such as green energy assets. If hydroponics takes off there may also be a long-term decrease in the use of greenhouse space. Food hubs in large conurbations could support those areas as well.

Q: How does the funding work?

JLJ: We were privately funded initially by venture capital; then we had some individual high-net-worth backers who came on board. Once we were operating, Ocado bought into us.

Q: What are your next steps?

JLJ: We'll continue to operate our first unit in Scunthorpe. We are also exploring a number of exciting opportunities – three in the UK and others internationally – with a view to building a new and improved facility in the next six to eight months, to operate in the same way that we are already do in Scunthorpe.

Of course you won't see our name on the shelves, we went white label so that I didn't have to deal with budgets. Such an approach would have presented a whole different set of challenges, in that you have to have marketing departments and social media among other things.

James Lloyd-Jones is managing director and founder at JFC james@jonesfoodcompany.co.uk

Related competencies include: Agriculture