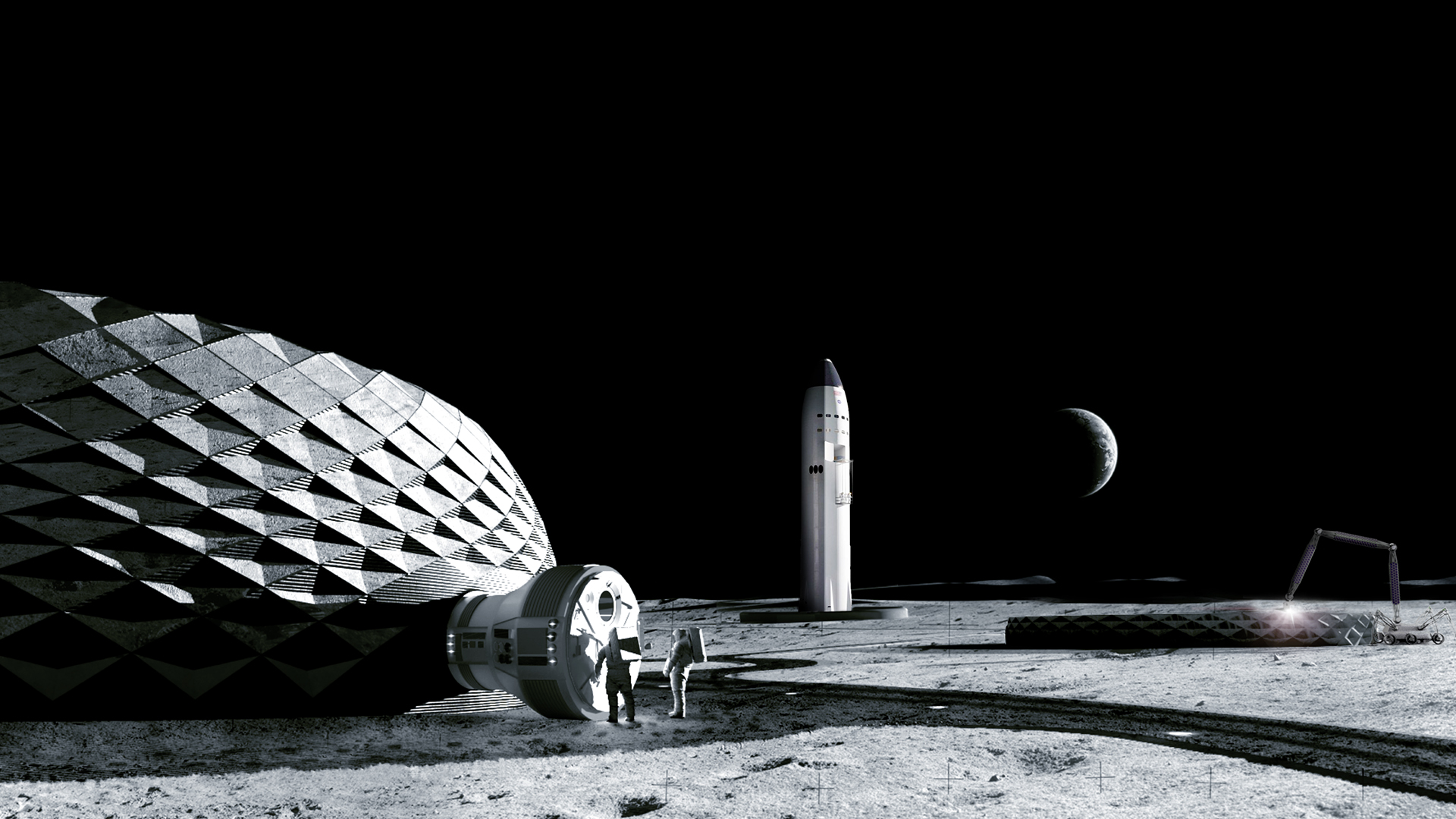

ICON / Olympus lunar construction system concept

Where once extended voyages to explore the Moon were the stuff of science fiction fantasies, the US space agency, NASA, draws ever closer to making them a reality.

In 2022, NASA launched the Artemis programme, a manned orbit of the Moon. In 2026, Artemis II will transport astronauts to walk on its surface for the first time since the Apollo programme finished in 1972.

If that is successful, in 2027, Artemis III is planned. It will bring not only humans to the Moon, but Olympus, an enormous, self-propelling 3D printer. Built by Texas-based housing developers, ICON, who have pioneered the use of 3D printed construction, the Olympus system will aim to prove the feasibility of building on the Moon by fabricating a simple landing pad.

Should the landing pad trial go to plan, NASA will work with the European Space Agency (ESA) on Artemis IV, which will create the lunar gateway, the first space station orbiting the Moon. This will assist with creating habitable structures there by 2030. By 2040, the agencies expect to have established a semi-permanent human lunar presence.

But how? While transporting Olympus to the Moon is a theoretically simple possibility, transporting the cements and polyamides needed for 3D printing is impractical. Professor Patrick Suermann of Texas A&M University, which is collaborating with NASA on the Artemis programme, neatly estimated that every additional kilo of weight on a space mission costs $1m.

Instead, Olympus will work with the dust and gravel, known as regolith, found on the Moon which extends up to 70m beneath its surface. So far, so ingenious. But regolith is a difficult material to work with – it is so abrasive that it is highly dangerous to humans, especially if inhaled. There is no established water supply on the Moon with which to mix it. And, even if there were, the lack of pressure on the Moon means that the resulting paste could not be adequately compacted to create a building material.

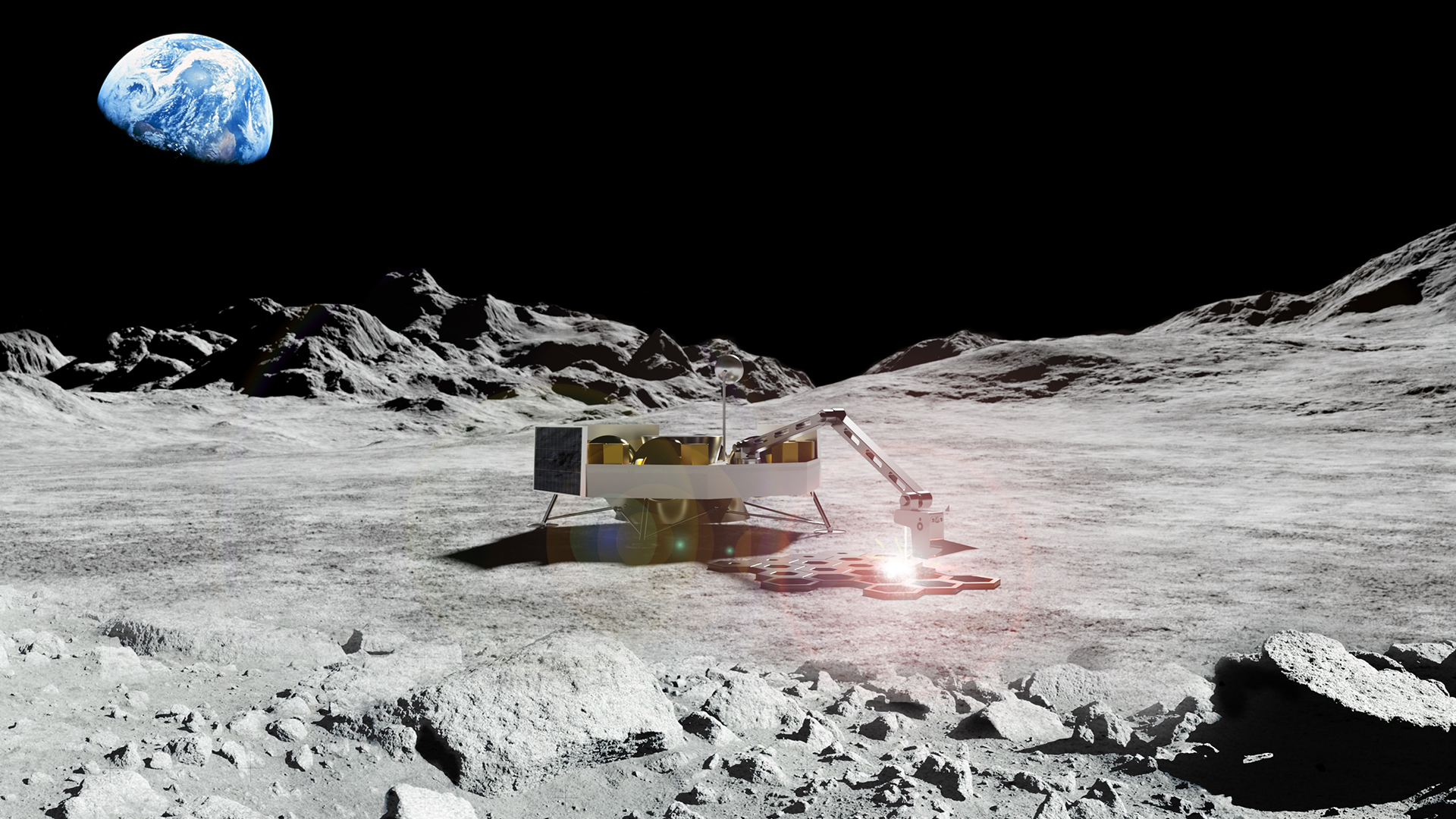

Geologists at NASA’s Marshall centre in Alabama have been studying tiny – and extremely finite – samples of regolith brought back from the Apollo missions. They have discovered that the regolith can be melted using lasers to make a highly durable material: both structurally hard and able to withstand temperatures of almost 1,900oC. This will be the building material of the Olympus system.

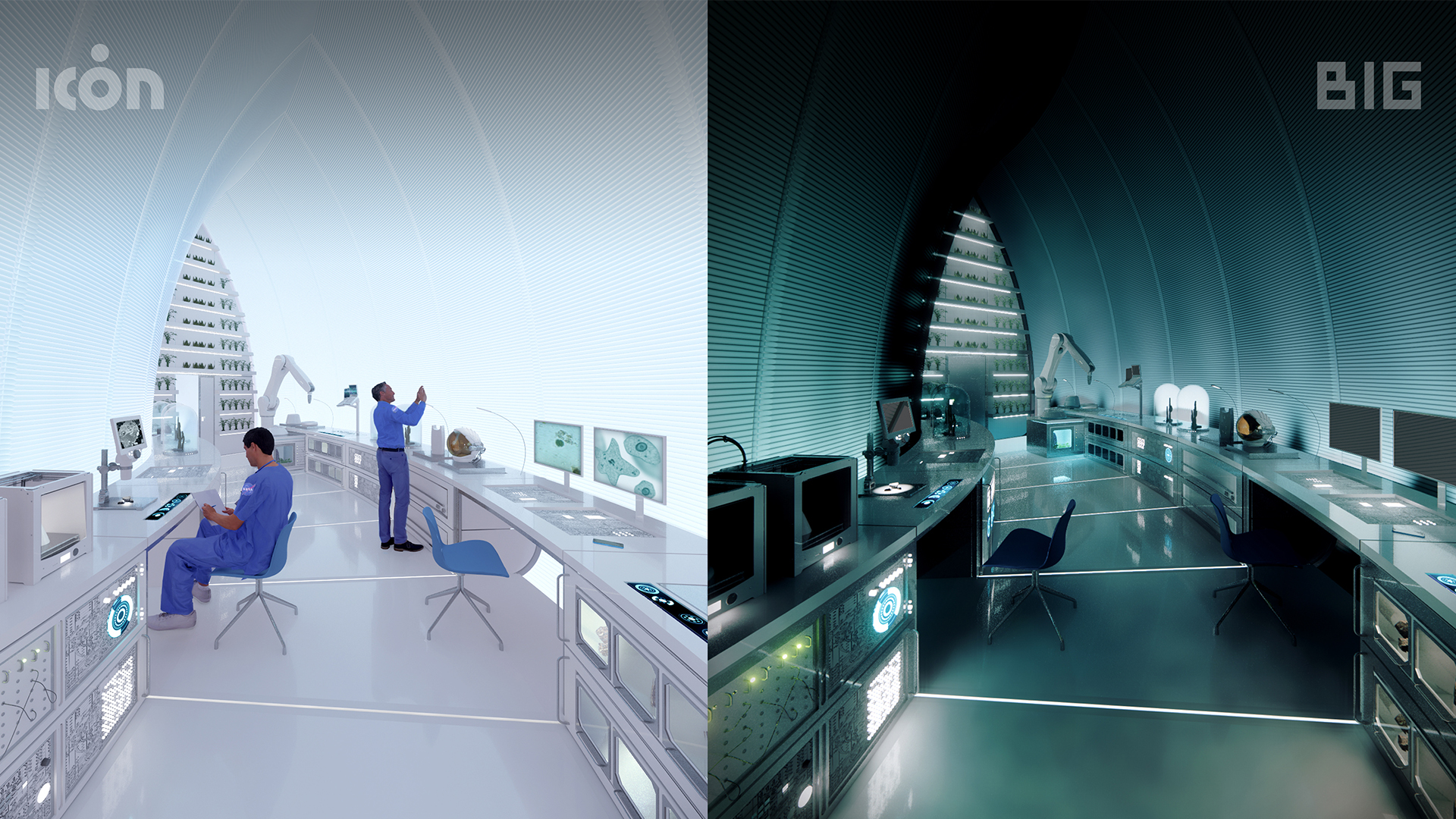

The ICON renders of the resulting building – designed by the Danish architectural practice, Bjarke Ingels Group – show an elegant, pineapple-like building with a sliver of Earth illuminated in the background.

But Sobha Rani FRICS, managing director of Veadhik Consultants in India, is wary of the unique challenges of 3D printing on the Moon. “One of the primary obstacles to implementing 3D printed construction on the lunar surface is the extreme and inhospitable environment, characterised by vacuum conditions, significant temperature fluctuations, intense radiation, and pervasive lunar dust,” she says.

“Additionally, reliance on in-situ resource utilisation (ISRU) to source construction materials presents technical challenges. The complexity is further compounded by the need for fully automated, large-scale construction systems capable of operating remotely in such a demanding and isolated setting.”

A lunar gold rush

This is a real space race, what one NASA official dubbed a “lunar gold rush”. The Moon’s surface area is 38 million km2 – significantly larger than Africa’s 30 million km2 – and likely to be quite varied. It gives scientists a wealth of elements to study and explore, and, potentially, minerals and materials to exploit.

Apart from ESA, who have their own Norman Foster-designed building ideas, there are various other space agencies competing to colonise the Moon: China’s Chang'e Project had its first successful lunar touchdown in 2013 and has since reached the far side of the Earth’s satellite. The country aims to have landed humans on the Moon by 2030. In 2023, India landed a space rover at the lunar south pole. Russia has also declared an interest in lunar exploration although it – as part of the former USSR – last landed a spacecraft there in 1976.

Such is the dash to launch further landings on the Moon, that the World Monuments Foundation has issued a warning about preserving the known artefacts and traces of human contact from previous missions “to protect this rich legacy for posterity” and avoid “exploitative visitation, souveniring, and looting by future missions and private lunar exploration”. It is not clear how this aim sits with plans to use regolith to build there and explore the Moon’s potential for resources.

There are also going to be plenty of intriguing potential dilemmas for surveyors to deal with. “Quantity surveyors involved in lunar construction will face a highly unconventional set of challenges shaped by the Moon's extreme environment and operational limitations,” says Rani.

“These challenges include sourcing non-traditional materials, with limited access to Earth-based supply chains, and working within conditions marked by severe temperature variations, radiation, and low gravity. Traditional cost management methods must be redefined to accommodate the absence of past benchmarks and the unpredictable nature of lunar projects.

“Given the lack of direct experience in extraterrestrial construction, cost estimations will need to be flexible and data-informed, accounting for technical uncertainties and evolving mission parameters.

“Collaboration across disciplines – particularly with engineers, aerospace experts, and systems designers – will be essential for the technical demands of lunar infrastructure development.”

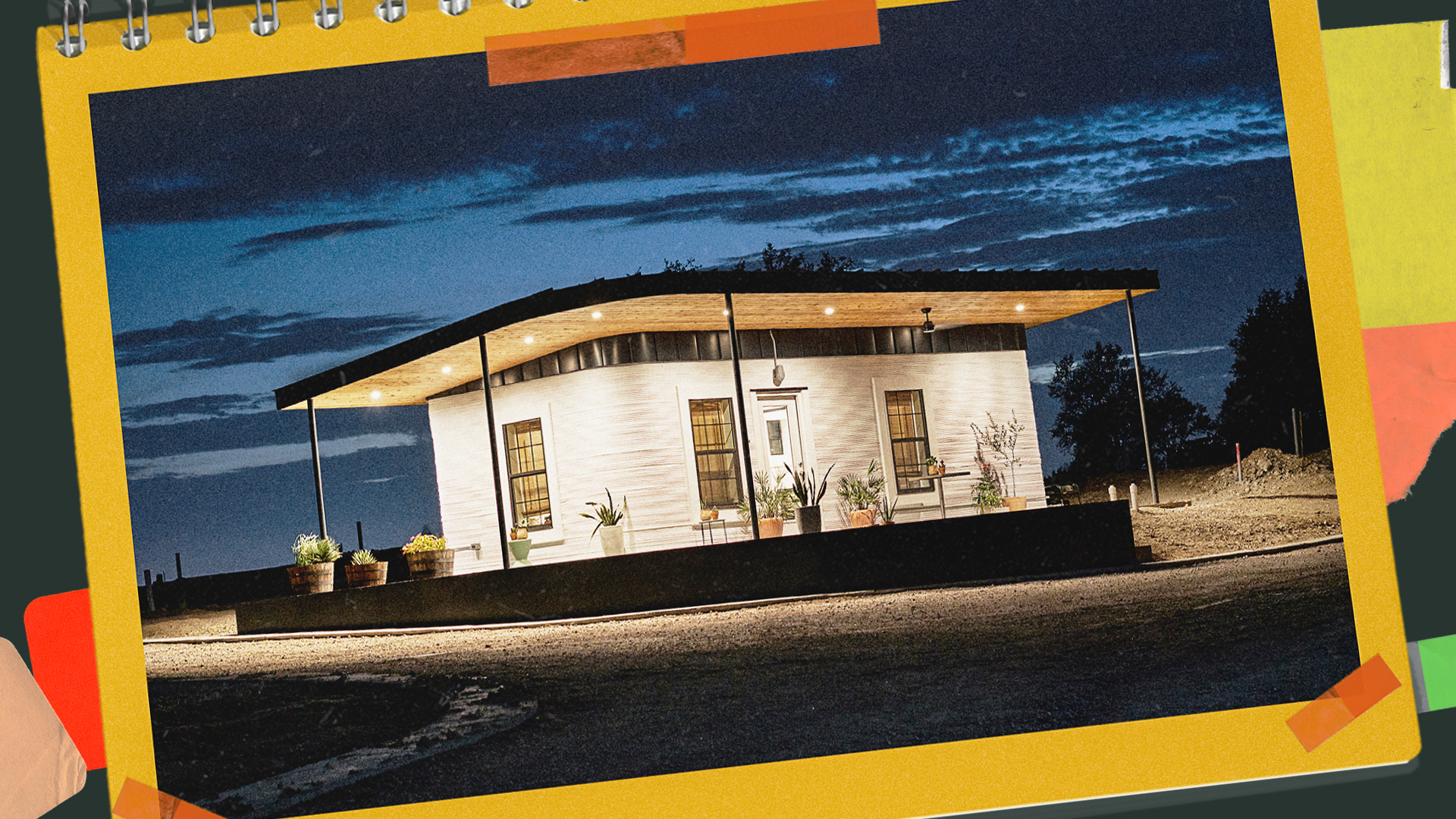

So far, ICON has received about $87m in grants from NASA to develop its lunar technology, part of which has been used to build its Moon Box, a sealed facility which mimics some lunar conditions. It has also built the Mars Dune Alpha building at NASA’s Johnson centre in Houston, Texas, using conventional 3D printing methods. In 2023, a group of four researchers were sealed inside the 155m2 structure for more than a year to monitor what life would be like on the red planet – while there, they experienced a series of simulated emergencies to stress test their reactions.

However far away the Moon seems, NASA’s ambition is to use it as a staging post on its long-term mission: to establish a presence on Mars.

“Quantity surveyors involved in lunar construction will face a highly unconventional set of challenges” Sobha Rani FRICS, Veadhik Consultants