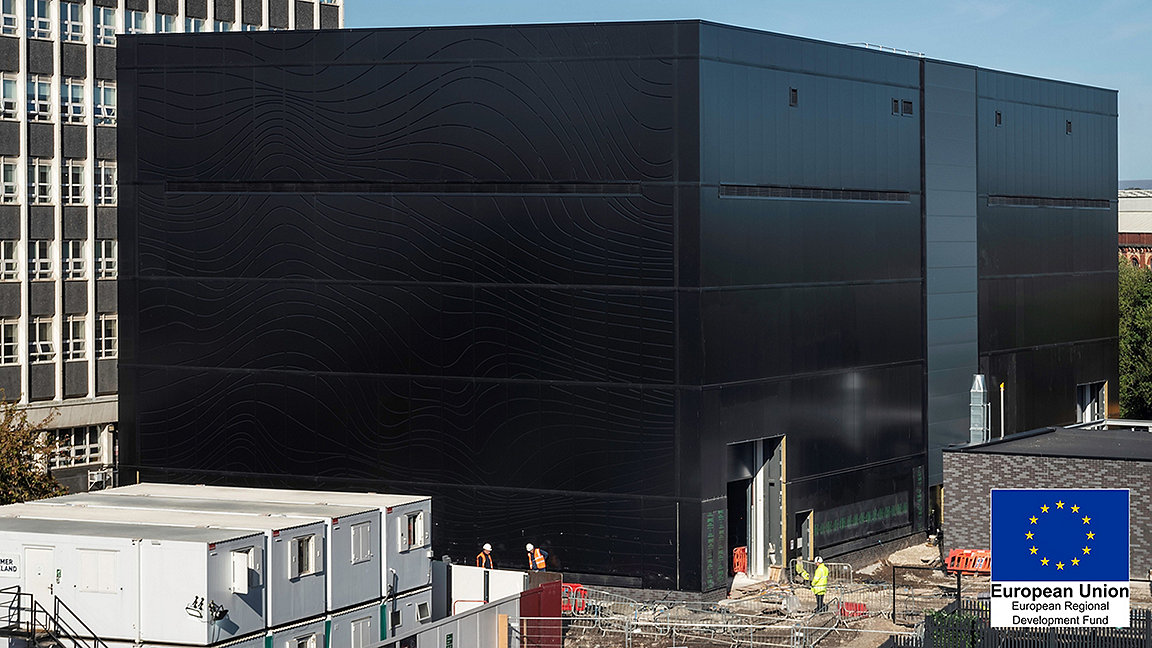

Energy House 2.0 in November 2021 © McCoy Wynne for University of Salford Art Collection

Energy House 2.0 at the University of Salford is due for completion in February. Part-financed by the European Regional Development Fund, the £16m project represents a major investment in the transition to net-zero homes.

The launch of the facility will be timely. As host of the recent COP26, the UK government committed in its October net-zero and heat and buildings strategies to change the way we power and warm our homes.

The proposed Future Homes Standard also makes far greater performance demands, targeting emissions reductions of 75–80% for 2025. But traditional building methods may not be up to the task.

The government's commitment to low-carbon technologies such as air-source heat pumps, district heating and potentially hydrogen means we need to improve the performance of new and existing homes. This will require new technical approaches.

Off-site manufacture, low-carbon heating technologies and smart domestic energy systems, which incorporate renewables and energy storage, will all help. But we will need to innovate rapidly and understand how these technologies perform in practice as whole systems.

A new way of testing

In 2011, Energy House Laboratories at the University of Salford changed the way low-carbon innovations could be assessed. The first facility it developed was the Salford Energy House, a Victorian end-terrace in an environmental chamber.

This enabled sustainable retrofits to be tested at a whole-house scale in repeatable conditions, establishing performance in a matter of weeks. By comparison, demonstrators can only provide limited data while large-scale field trials are costly, and both take many months.

However, the design of the original Energy House was limited in terms of archetype, which represents only 20% of UK homes. Furthermore, only limited weather conditions could be simulated. Energy House 2.0 will instead allow different types of home to be tested under much wider environmental conditions.

Constructing Energy House 2.0

Energy House 2.0 is 48m long, 22m wide and 19m tall. It consists of two 380m2 environmental chambers, which generate identical environmental conditions. They can create temperatures between –20C and +40C, while rigs will provide wind, rain and snow. The rigs also include lamps that replicate solar gain as closely as possible. The two chambers are serviced by a central core, which houses workshop and laboratory spaces, control systems and water tanks.

Work on the project started in August 2020 with the relocation of the existing car park. The first phase of construction on groundwork elements then began. This involved the creation of two large pits and the concrete foundations for the building.

The pits were designed to provide realistic ground conditions. Siting these pits in the base of the chambers minimises the impact of the external environment on test homes. It means we can provide a realistic assessment of heat loss through the ground.

Unlike the original Energy House on its concrete plinth, this purpose-built facility was able to include a heat-flux sensor array. This allowed ground conditions to be fully evaluated in the context of building performance.

Next, the steel frame was put up and the insulation added. This is more than 320mm thick to condition the chambers effectively and ensure high performance.

Once the building shell was completed and the pits were filled with soil, the chambers and environmental control systems were constructed. Costing around £6m, the heating, ventilation and air conditioning represents one of the largest packages in the project. After this will come the commissioning phase, which is due to be completed in early February.

Partners to help in demonstration phase

Once construction is finished there will be a demonstration phase. We will work with three partner consortia to build different properties that improve our understanding of net-zero homes.

Bellway: The property developer is building a house to test how low-carbon heating technologies will work in combination with building fabric, efficient services, and renewable energy in practical scenarios.

Muse: This developer will build apartments to explore commercially viable net-zero innovation for construction. The findings will inform the sustainability of the Crescent Masterplan, a £2.5bn regeneration scheme in Salford.

Saint-Gobain: The low-impact building developer will be researching modern, light and sustainable construction, to see how it can help meet and exceed standards for homes in the future. It will use the facility for practical testing of building performance and new products.

Alongside the Energy House Laboratories team, the partners' work represents a detailed study into the future of new-build housing that will be central in the transition to net zero.

In the short to medium term, the team anticipates that the greatest demand will be for researching integrated energy systems. These use smart technology to combine renewables, storage, heating, and electric vehicle charging into single systems. There is also demand to better understand energy consumption and fabric performance in homes manufactured off site.

In the longer term, we see opportunities beyond the built environment. Energy House 2.0 is one of the largest environmental chambers in Europe, so the team can engage with vehicle manufacturers, assess emergency shelters, and look at how machines or even people perform under different conditions.

Prof. Will Swan is the director of Energy House Laboratories in the School of Science, Engineering and Environment at the University of Salford

Contact Will: Email

Dr Richard Fitton is a reader in energy efficiency in the School of Science, Engineering and Environment at the University of Salford

Contact Richard: Email

Related competencies include: Construction technology and environmental services, Sustainability